Sharpening materials for dental instruments

The correct utensils for optimal sharpening results

The best sharpening utensils alone cannot sharpen your dental instruments. The correct method for sharpening the instruments is particularly important. Instrument maintenance is of significant importance. You can find out what to be aware of when sharpening dental hand instruments here or in our new American Eagle Instruments sharpening video.

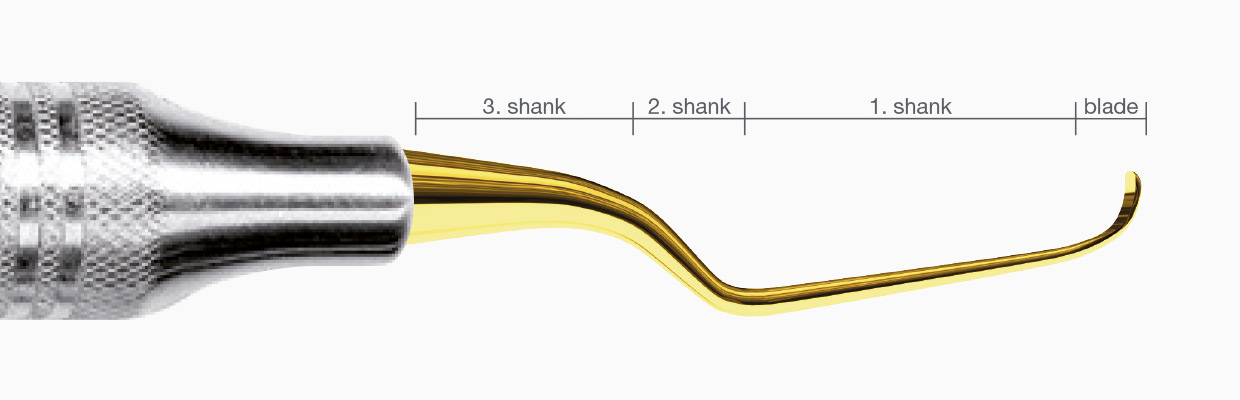

Sharpening of scalers and curettes

How to properly sharpen perio instruments

AE SA CC/F

Simply Sharp Ceramic Stone

8,9 x 2,5 cm

AE SA CCS

Ceramic Stone Super

AE SA DS

Diamond Stone

10,1 x 2,5 cm

AE SA STP

Sharpening Test Stick (6ct pack) – AE SA STP

Sharpening Test Stick (single) – AE SA STS

AE SA MEL

Simply Sharp Lupe

AE SS STN

Arkansas Sharpening Stone

Particularly fine sharpening stone, ideal for sharpening scalers and curettes. Natural Arkansas stone is characterised by its particularly low abrasiveness and, therefore, little material removal from the instrument. It should always be used together with suitable sharpening oil.

AE SS SURG

Surgical Arkansas Sharpening Stone

Particularly fine sharpening stone, ideal for sharpening surgical instruments such as root elevators, bone curettes, bone chisels, etc. The incorporated radii assist with correct execution. Natural Arkansas stone is characterised by its particularly low abrasiveness and, therefore, little material removal from the instrument. It should always be used together with suitable sharpening oil.

AE SS TNCY

Conical Arkansas Sharpening Stone

Particularly fine, conical sharpening stone – for finishing the facial surfaces of scalers and curettes, but also suitable for surgical instruments. Natural Arkansas stone is characterised by its particularly low abrasiveness and, therefore, little material removal from the instrument. It should always be used together with suitable sharpening oil.

Before it comes to sharpening your hand instruments

Used, contaminated instruments should be cleaned and disinfected as soon as possible. Be sure to follow the instructions of the detergent and disinfectant manufacturers as well as the instructions for the processes in the washer-disinfector (WD) or thermal disinfector (TD).

Never use drill brushes or other abrasive tools to clean the instruments. Only use soft plastic brushes.

Dental instrument cassettes such as GALAXIE cassettes are recommended for the efficient and resource-saving sterilisation, transport and storage of instruments. They keep the hand instruments fixed securely and separately from each other.

Optimal preparation for sharpening instruments

If the hand instruments are not prepared and handled properly before sharpening, the aggressive chemicals can corrode the surface of the instruments. Concentration, retention time and water quality have an influence on the quality and life span of the instruments.

Drill brushes or other abrasive tools will damage the surface. Rust formation and dirt deposits may occur. Safe, contact-free storage ensures that the instruments have a long service life. GALAXIE instrument cassettes also lower the risk of injury and infection and make it possible to put together individual instrument sets.

To sharpen or not to sharpen –that is the question here

After each treatment, you should check the stainless steel instruments and sharpen them if necessary. Below you can see why you should always work with sharp instruments.

Dull curettes (cross-sectional view)

Blunt instruments only partially “polish” or remove deposits. In addition, there is an increased risk of breakage due to the increased pressure applied while working. The permanent use of blunt instruments also increases the physical strain due to the higher pressure. This puts a strain on both the patient and the practitioner’s health and can lead to carpal tunnel syndrome, among other things.

Sharp curettes(cross-sectional view)

Only a sharp edge allows you to work effectively and ergonomically. Find out more about ergonomic working methods in dental treatment and the maintenance of your instruments in our category.

Admittedly, sharpening is time-consuming. To do this effectively, you need the right tools.

In addition to the necessary materials such as whetstone and oil, an optimal working environment, a free area with enough space and good lighting are also important. A magnification or a magnifying glass as well as a swivel vice that can be adjusted in the axes are also ideal – this is the only way to ensure the correct alignment of the instruments. Position the instrument at eye level.

The Simply Sharp ceramic stone

- 1. Upper side: coarse abrasive surface with groove

- 2. Lower side: finer removal side without groove

- 3. Rounded edges for curettes and for deburring all instruments

- 4. The groove is used to sharpen the front rounding of curettes

Frequently asked questions about sharpening dental instruments

How do I choose the right whetstone?

Very fine Arkansas stones must be moistened with grinding oil. They often differ slightly in their tint, but this does not denote a difference in quality. Arkansas natural stones are recommended for regular sharpening with little material removal.

The more abrasive variants – for example, India – are usually synthetic and must also be used with oil or water. Such stones are only suitable for “emergencies” as they remove a disproportionate amount of material.

Diamond whetstones have peculiar characteristics. The less abrasive variants can be used together with oil for regular resharpening.

The shape of the stone also plays a role. For scalers and curettes, we recommend having a conical or tapered version available for deburring the facial surface. Variants with grooves can be used for surgical instruments or excavators.

When it comes to sharpening oil, material compatibility is important – manufacturers usually offer their own product. Medical white oil has also proven its worth.

Periodontal instruments need to be sharpened regularly. If an instrument is already too blunt, the correct geometry and a sharp cutting edge can no longer be produced. Therefore, always check the sharpness of the instruments after sterilisation.

How do I recognise a blunt hand instrument?

Firstly, a visual assessment of the instrument is carried out – if the cutting edge is shiny, the instrument is blunt. It is also helpful to use a plastic test stick, which does not add further wear to the cutting edge.

Tilt scalers and universal curettes by about 20 degrees – you can check the sharpness by the “bite” or a slight “ding”. If the instrument just slides across the surface, it may already be too late – or high time for sharpening.

Gracey curettes do not need to be manually tilted for testing; align the terminal shank parallel to the test stick.

When should I replace my hand instruments?

You should replace the instruments at the latest when one of the following criteria is met:

- The functionality is no longer guaranteed – for example, a curette has become a scaler.

- About 20% of the material has already been removed. After that, the risk of an instrument fracture increases significantly.

- The instruments are ground with, for example, several cutting edges.

The replacement is primarily for the protection and well-being of your patients. Tips that are too thin break very easily. If the working end is worn out, the patient is subjected to too much pressure and your ergonomics as a practitioner also suffer considerably. You can find more information on the subject of sharpening instruments and ergonomics in our instrument guide.

Which type of sharpening does American Eagle Instruments recommend?

The preferred and safest method of instrument sharpening is sharpening with a vice; this allows you to align and fix the instrument perfectly.

Can I also sharpen my XP instruments?

Instruments with XP Technology® must never be sharpened. This would only wear away the super-hard alloy of the working ends and ruin the instrument tips. The particularly hard surface treatment of the instrument blades makes the instruments much more durable and wear-resistant. Time-consuming sharpening of instruments is thereby eliminated. Learn more about XP Technology®.

Learn how to sharpen correctly!

We offer regular sharpening courses to provide you with the knowledge to keep your instruments in an optimal condition for long-term use.

Do you have any questions?

We’re here for you!

Want to find out more about our products?

Schedule a consultation with our product experts or send us your request in advance using our contact form.